ThreadLoc® chemical

Innovative chemical thread locks

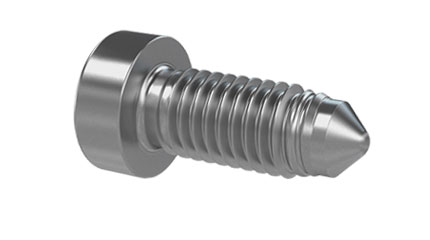

In ThreadLoc® ARNOLD has created a full product range to meet every screw fastening need. So you will find the right locking, insulation and sealing solution for every application.

The crucial factor in securing against vibration, corrosion, heat and screw deformation is therefore selecting the correct screw lock procedure. ARNOLD’s ThreadLoc® range provides a comprehensive range of mechanical and chemical locking systems for screw fastenings. There are two versions available for sealing and damping screw fastenings.

The first is to generate the sealing or damping function in the thread, and the second is generating it directly below the screw head. Both systems are thus directly integral to the assembly element and require no further measures.

Advantages

Sealing and damping in the thread:

Thread seals and dampers are dry or touch-proof, dry-on coatings which fill the thread gap, but which produce no chemical reaction. They are thus 100% ready for use immediately after application.

- Good seal and damping properties

- Resistant to aggressive media

- Ready coated

Sealing and damping below the head:

Below-head sealing and damping systems in polyamide or polyolefin are produced in two ways – by fusing the plastic directly onto the underside of the screw heads, or by applying a nylon ring, which is then fused onto the underside of the screw head.

- Good seal and damping properties

- Can be used many times

- Effective against contact corrosion

- Low friction, so suitable for automated assembly

ThreadLoc® with adhesive:

This solution bonds and also seals If provides reliable locking against self-actuating detachment.

- Dry, touch-proof locking coat ready for use at any time

- Once cured, unaffected by oil and grease

- Screw and fastener form a single unit and thus the locking element cannot detach

- No extra stockholding required

- Easy and secure assembly

ThreadLoc® with clamping:

This variant prevents a screw fastening from detaching completely (counter effect to unscrewing rotation; however, it cannot be arrested).

- Simultaneous clamping and sealing function against fluids and gases (with all-round coating)

- Dry, touch-proof locking coat ready for use at any time

- Resistant to almost all aggressive media

- Screw and fastener form a single unit, no need for mechanical locking elements, no dual stockholding required; no additional assembly work, impossible to forget the locking element; non-detachable

- Easy and secure assembly

- Loads can be applied immediately after assembly

In ThreadLoc® ARNOLD has created a full product range to meet every screw fastening need. So you will find the right locking, insulation and sealing solution for every application.

The crucial factor in securing against vibration, corrosion, heat and screw deformation is therefore selecting the correct screw lock procedure. ARNOLD’s ThreadLoc® range provides a comprehensive range of mechanical and chemical locking systems for screw fastenings. There are two versions available for sealing and damping screw fastenings.

The first is to generate the sealing or damping function in the thread, and the second is generating it directly below the screw head. Both systems are thus directly integral to the assembly element and require no further measures.

Advantages

Sealing and damping in the thread:

Thread seals and dampers are dry or touch-proof, dry-on coatings which fill the thread gap, but which produce no chemical reaction. They are thus 100% ready for use immediately after application.

- Good seal and damping properties

- Resistant to aggressive media

- Ready coated

Sealing and damping below the head:

Below-head sealing and damping systems in polyamide or polyolefin are produced in two ways – by fusing the plastic directly onto the underside of the screw heads, or by applying a nylon ring, which is then fused onto the underside of the screw head.

- Good seal and damping properties

- Can be used many times

- Effective against contact corrosion

- Low friction, so suitable for automated assembly

ThreadLoc® with adhesive:

This solution bonds and also seals If provides reliable locking against self-actuating detachment.

- Dry, touch-proof locking coat ready for use at any time

- Once cured, unaffected by oil and grease

- Screw and fastener form a single unit and thus the locking element cannot detach

- No extra stockholding required

- Easy and secure assembly

ThreadLoc® with clamping:

This variant prevents a screw fastening from detaching completely (counter effect to unscrewing rotation; however, it cannot be arrested).

- Simultaneous clamping and sealing function against fluids and gases (with all-round coating)

- Dry, touch-proof locking coat ready for use at any time

- Resistant to almost all aggressive media

- Screw and fastener form a single unit, no need for mechanical locking elements, no dual stockholding required; no additional assembly work, impossible to forget the locking element; non-detachable

- Easy and secure assembly

- Loads can be applied immediately after assembly