ARNOLD sheet-metal joining technology

Optimum fastenings for your lightweight engineering applications

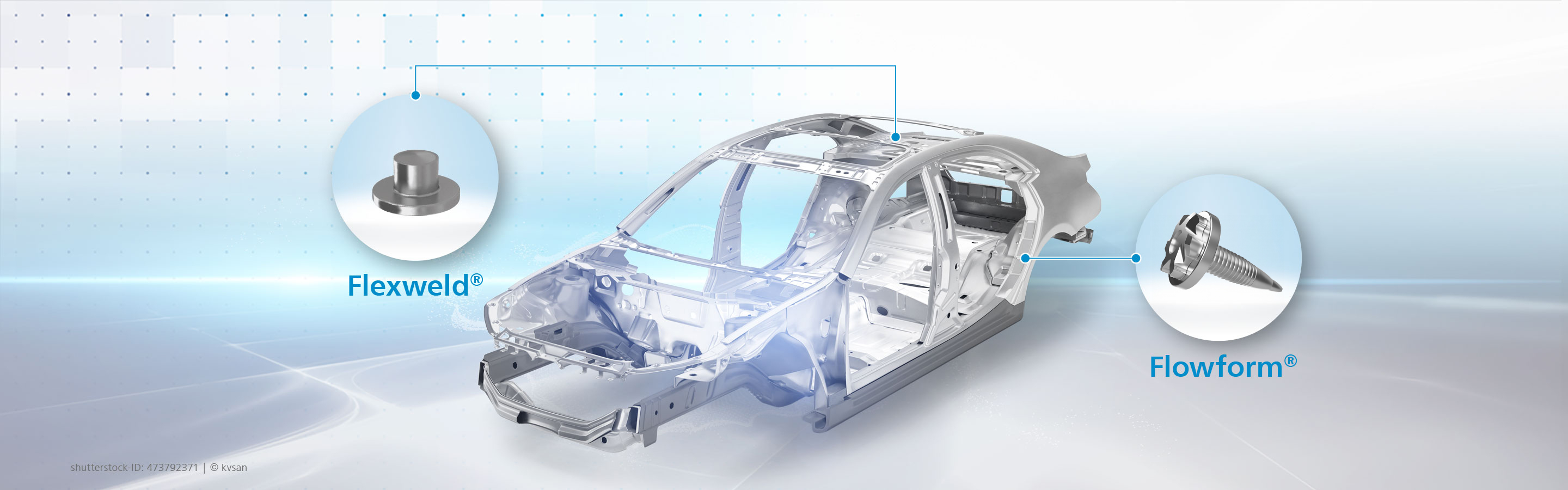

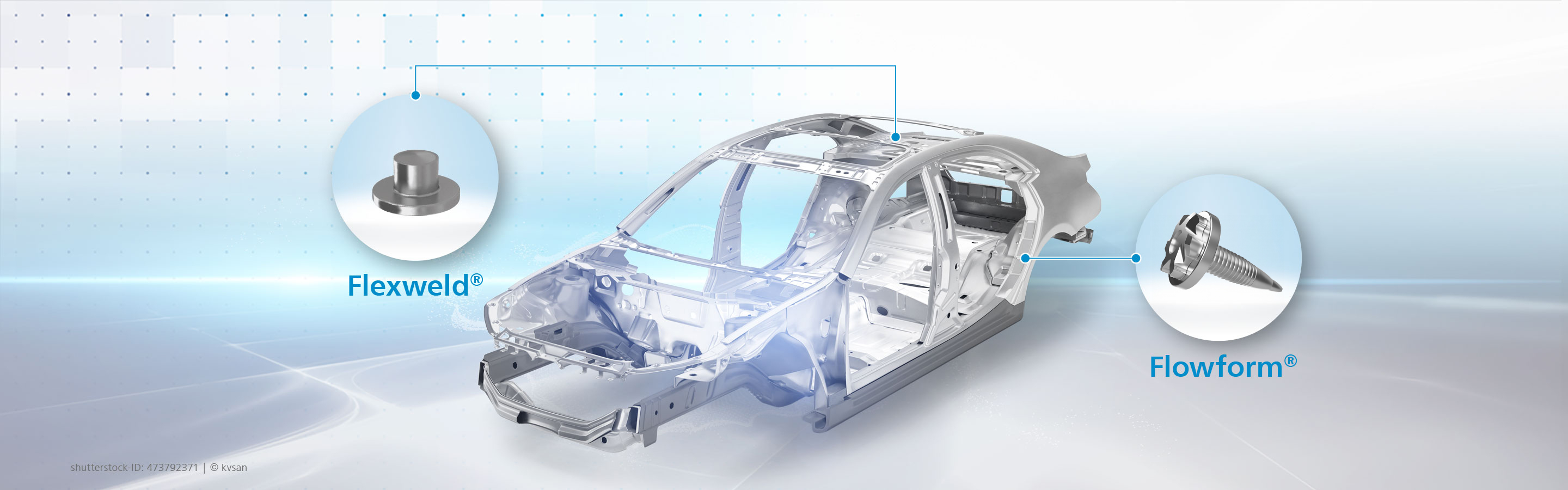

When joining sheet metals the trend is towards ever thinner sheet metals, and the fasteners used need to be higher strength than ever. Combinations of highly disparate materials make the task even more demanding and design engineers in the automotive industry are faced with new challenges – especially when creating a secure connection between super-high-strength aluminium and steel sheets, or a composite material.

This is where ARNOLD UMFORMTECHNIK comes into your picture. With Flexweld®, our unique resistance element welding technology, for the first time it is now possible to join aluminium to heat-formed steel. And with the Flowform® Plus, the enhanced flowhole and thread-forming screw, super-high-strength sheet metals can be securely fastened even without predrilling into the top layer.

Sheet-metal fastenings, they stick to what they promise.

See ARNOLD's innovative fastening technologies in use.

Talk to our experts about your particular application.

For the best possible fastening, we offer support to users by carrying out feasibility tests in our metal-joining laboratory, using original materials.

Nadine Schmetzer, Research and development, Sheet Metal Joining Technology

ARNOLD metal-joining technologies give you more than just advantages; they provide true added value.

Resistance element welding with Flexweld®:

- Significant weight-saving, providing long-term reduction in CO2 emissions.

- Joining lightweight materials to super-high-strength sheet metals.

- Can be incorporated into existing assembly lines since it is possible to use the same production and welding equipment.

- No additional qualification for workers needed.

- Complete system including full feeder and processing technology.

- Mixed production possible by adapting the spot weld gun software.

- Reliable high-volume production.

- Can use standard operating materials.

Flowhole-forming Flowform® Plus screw:

- A joining technology with single side access.

- Fewer application constraints (can join sheet steel up to 1000 Mpa strength).

- Detachable fastening.

- Joining materials of different types and of the same type.

- Can make joins without predrilling into the top layer.

- Less gap formation.

- Reducing weight by decreasing the diameter of the element.

- Flange width can be reduced with the smaller drive.