Flowform® Plus

The lightweight variant for fastening sheet metals

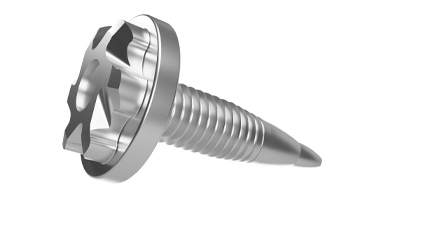

Flowform® Plus from ARNOLD is a flowhole-forming and thread-forming screw that further enhances our well-proven Flowform® solution – with a smaller diameter and – despite having the same length – weighing 25% less. Thanks to the polygonal cross-section in the functional tip, you benefit from lower joining forces when forming the holes, or – using the same force – shorter hole-forming times.

Benefits

The defined tip radius at the tip end means that the tip of this fastener can accept a higher load. So Flowform® Plus is perfectly suited for high strength sheet steels. The polygonal cross-section in the thread-forming area reduces the tapping torques and prevents chip formation during the insertion process. In the bearing thread area, the round shaft cross-section ensures improved load capacity and provides a metric nut thread. The underhead channelling accepts the material raised during the hole-forming process, while the external force application with its lead-in chamfers ensures optimum location, thus reducing cycle time. The load flank of the force application optimises the torque force transmission.

Characteristics

Firstly, Flowform® Plus differs in dimension from Flowform®. While Flowform® screws are usually 5 mm in diameter, the Flowform® Plus screw has a diameter of just 4 mm. The base material and the heat treatment are also new features.

Advantages

- 25% weight saving due to size reduction

- Joins up to 1,000 Mpa strength sheet steels and around ≤ 1 mm thick, in combination with aluminum screw-in parts

- Ideal for joining aluminum sheets without pre-drilled holes, while also reducing gap formation

- Very good fastening properties due to a ductile and very-high-strength screw material

- Uses existing series production equipment

- In thicker joint combinations, no pre-drilled hole is required in the clamping part

- The fastenings can be undone if necessary

Flowform® Plus from ARNOLD is a flowhole-forming and thread-forming screw that further enhances our well-proven Flowform® solution – with a smaller diameter and – despite having the same length – weighing 25% less. Thanks to the polygonal cross-section in the functional tip, you benefit from lower joining forces when forming the holes, or – using the same force – shorter hole-forming times.

Characteristics

Firstly, Flowform® Plus differs in dimension from Flowform®. While Flowform® screws are usually 5 mm in diameter, the Flowform® Plus screw has a diameter of just 4 mm. The base material and the heat treatment are also new features.

Benefits

The defined tip radius at the tip end means that the tip of this fastener can accept a higher load. So Flowform® Plus is perfectly suited for high strength sheet steels. The polygonal cross-section in the thread-forming area reduces the tapping torques and prevents chip formation during the insertion process. In the bearing thread area, the round shaft cross-section ensures improved load capacity and provides a metric nut thread. The underhead channelling accepts the material raised during the hole-forming process, while the external force application with its lead-in chamfers ensures optimum location, thus reducing cycle time. The load flank of the force application optimises the torque force transmission.

Advantages

- 25% weight saving due to size reduction

- Joins up to 1,000 Mpa strength sheet steels and around ≤ 1 mm thick, in combination with aluminum screw-in parts

- Ideal for joining aluminum sheets without pre-drilled holes, while also reducing gap formation

- Very good fastening properties due to a ductile and very-high-strength screw material

- Uses existing series production equipment

- In thicker joint combinations, no pre-drilled hole is required in the clamping part

- The fastenings can be undone if necessary