Production

Strong performance across the board.

Your requirements are varied – and extraordinarily challenging. Our production spectrum is adjusted to meet them. This means that you can obtain a huge range of services from a single source – ARNOLD.

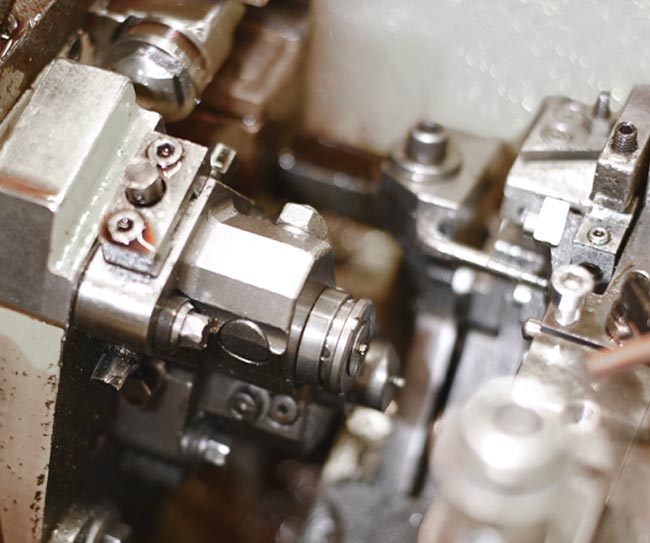

Tool-making

ARNOLD's tool-making facility with the latest equipment gives optimum support to the manufacturing departments, while also ensuring flexibility and effectiveness.

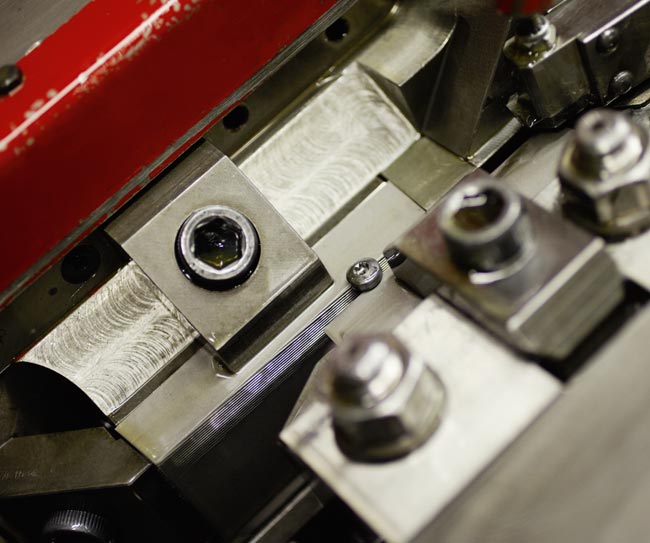

Double-strike and multi-stage pressing

Do you need large quantities? In our double-strike section, we are able to press large quantities of a very diverse range of products – under constant and meticulous process monitoring.

Thread rolling

We fulfil your need for standard or special threads and for parts with non-detachable washers from our own high-performance machinery.

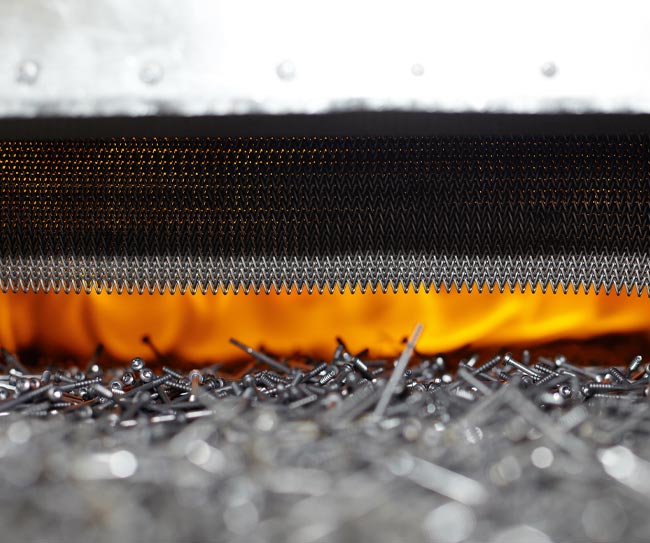

Heat treatment

We ensure shorter transfer times and optimised processes in our own fully automated hardening furnaces.

Surface treatment

At our own electro-plating facility, we provide coatings for a wide variety of standard surfaces for you – efficiently and to an outstanding quality.

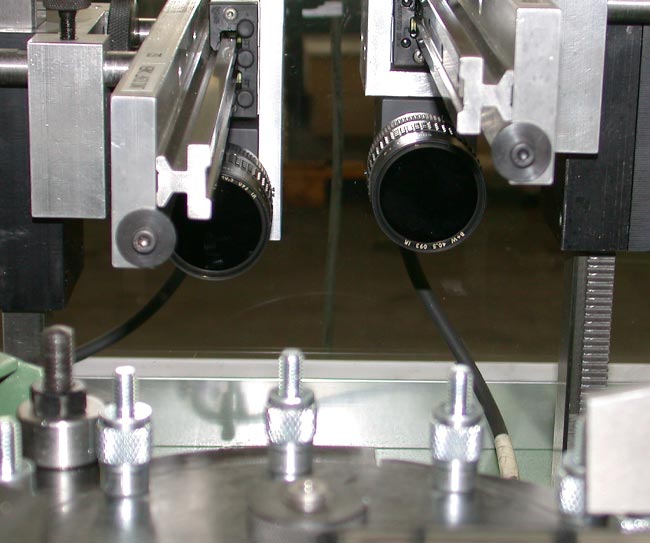

Automated sorting

Only the best is good enough for you. That's why we have implemented intelligent inspection technology such as automatic sorters and climate chambers – and continuous professional development for our staff, to achieve optimum quality.