Conform®

Cost-optimised multifunction parts

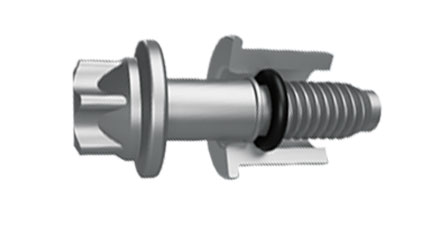

The Conform® product line covers complex cold-formed parts for numerous applications, which in many cases, ARNOLD designs as a customer-specific solution. Thanks to the metal-forming Conform® process, you can produce parts more economically than conventional screw machined or turned parts.

Characteristics

The ARNOLD Conform® product range includes complicated external contours, blind and through-holes, short, hard-to-convey parts, or products requiring center-hole machining. We have in-house heat-treatment and surface treatment facilities to handle the entire manufacturing process in-house in one continuous process.

Advantages

With our innovative multi-stage forming, you save up to 80% on bulk production runs compared with turned parts. Reasons for such enormous savings include the fact that less material is required for non-cutting forming. And multi-stage pressing delivers a much higher production output compared with conventional lathes.

The Conform® product line covers complex cold-formed parts for numerous applications, which in many cases, ARNOLD designs as a customer-specific solution. Thanks to the metal-forming Conform® process, you can produce parts more economically than conventional screw machined or turned parts.

Characteristics

The ARNOLD Conform® product range includes complicated external contours, blind and through-holes, short, hard-to-convey parts, or products requiring center-hole machining. We have in-house heat-treatment and surface treatment facilities to handle the entire manufacturing process in-house in one continuous process.

Advantages

With our innovative multi-stage forming, you save up to 80% on bulk production runs compared with turned parts. Reasons for such enormous savings include the fact that less material is required for non-cutting forming. And multi-stage pressing delivers a much higher production output compared with conventional lathes.

The Conform® product range

Conform® precision parts

We use the latest high-gloss polished and coated forming tools for our cold-forming process. This achieves a high level of precision, for example, for small and medium-sized drive shafts for electric motors (for windscreen wipers, window regulators, seat adjusters, ABS functional parts, and so on).

Conform® – toothed parts

Toothed parts were mainly manufactured in a cutting process with a finishing process that followed the heat treatment stage. ARNOLD produces toothed parts using the cold-forming method. This enables the following:

- Customer-specific external geometries

- Greater endurance strength

- Greater mechanical load resistance

- Press-smooth surfaces

- High accuracy of shape and position

- Saving on materials

Conform® hollow parts and nuts

The production of formed hollow parts by ARNOLD – for sensor housings, union nuts for hydraulic, braking, and fuel lines, or clinch nuts – is an incredibly economical, time-saving option. We also have other supplementary forming options for machine-finishing in-house.

Our cold-forming makes it possible to produce – even on thin-walled hollow parts – rolled external threads (chipless produced) and surfaces suitable for extreme corrosion requirements.

Conform® – bushes

The light constructions in the automotive industry require savings in materials and weight, yet using materials and components that possess load capacities. ARNOLD takes this development in hand with its plastic molded Conform® bushes. They turn potential weak spots into resistant functional elements and accept preload forces from screw connections, thus providing high length and diameter accuracy. The use of aluminum bushes saves even more weight, providing sophisticated solutions when combined with TAPTITE 2000® thread-rolling screws.

Aluminum Conform®

Complex extruded parts from our Conform® aluminum range (e.g. inserts, sleeves, sleeves, and nuts) are applied in synthetic materials. They are used to strengthen component parts in the form of functional elements with toothing and fits or a counterpart for self-tapping screw fastening. The alloy mainly used is EN AW 5754.