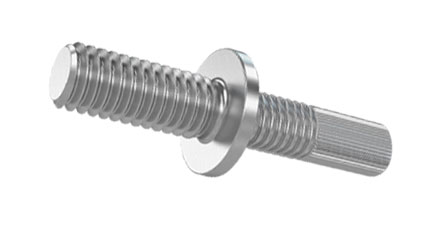

REMFORM® II HS™

The next generation

Just as with REMFORM® you can use REMFORM® II HS™ to fasten directly into plastic components. These offer major advantages over conventional metal components, notably due to the lower processing, assembly, and finishing costs. The narrow, asymmetrical thread profile of REMFORM® II HS™, enhanced by the radial tip thread crest and the curved load flank, provides optimized and particularly smooth material displacement.

Benefits

First of all, as it is tapped, the thread in this screw acts as a forming tool, and secondly, it acts as a positive form-locking fastening that prevents the screw from autonomous loosening. The low pitch of the load flank (just 10°) reduces the radial component Frad and, together with the larger thread loading depth, ensures that the screw fastening possesses a high clamping force. With the lower radial strain, the danger of the plastic cracking is reduced to a minimum. Optimised load support in the thread prevents any stress relaxation and protects even further against autonomous loosening.

Characteristics

The thread-tapping screw with its asymmetric thread profile is tightened into the prepared holes. As the screw is tightened the plastic flows towards the load flank, while the radial tip thread crest minimises radial hoop stress. Consequently, less plastic material has to be displaced to achieve the required profile depth in the nut thread. This again results in a low tightening torque, high overturn torque and high assembly reliability. REMFORM® II HS™ has a larger thread core and smaller thread pitch compared with its predecessor. Thus, it is ideal for use in harder plastics that are susceptible to cracking.

Advantages

REMFORM® II HS™ offers a crucial benefit over inserts in terms of time and cost savings.

- No need for additional joining elements

- No additional insertion processes

- Substantially reduces cycle time

- Improved material flow

- Low insertion torques

- High overtorques

- High pre-load force

- Good dynamic security

- Minimal tube load because of small flank angle

- High breaking torques

- Fastening is very secure against loosening

- High level of process reliability

Just as with REMFORM® you can use REMFORM® II HS™ to fasten directly into plastic components. These offer major advantages over conventional metal components, notably due to the lower processing, assembly, and finishing costs. The narrow, asymmetrical thread profile of REMFORM® II HS™, enhanced by the radial tip thread crest and the curved load flank, provides optimized and particularly smooth material displacement.

Characteristics

The thread-tapping screw with its asymmetric thread profile is tightened into the prepared holes. As the screw is tightened the plastic flows towards the load flank, while the radial tip thread crest minimises radial hoop stress. Consequently, less plastic material has to be displaced to achieve the required profile depth in the nut thread. This again results in a low tightening torque, high overturn torque and high assembly reliability. REMFORM® II HS™ has a larger thread core and smaller thread pitch compared with its predecessor. Thus, it is ideal for use in harder plastics that are susceptible to cracking.

Benefits

First of all, as it is tapped, the thread in this screw acts as a forming tool, and secondly, it acts as a positive form-locking fastening that prevents the screw from autonomous loosening. The low pitch of the load flank (just 10°) reduces the radial component Frad and, together with the larger thread loading depth, ensures that the screw fastening possesses a high clamping force. With the lower radial strain, the danger of the plastic cracking is reduced to a minimum. Optimised load support in the thread prevents any stress relaxation and protects even further against autonomous loosening.

Advantages

REMFORM® II HS™ offers a crucial benefit over inserts in terms of time and cost savings.

- No need for additional joining elements

- No additional insertion processes

- Substantially reduces cycle time

- Improved material flow

- Low insertion torques

- High overtorques

- High pre-load force

- Good dynamic security

- Minimal tube load because of small flank angle

- High breaking torques

- Fastening is very secure against loosening

- High level of process reliability

REMFORM® II HS™ is a trademark licensed by CONTI Fasteners AG