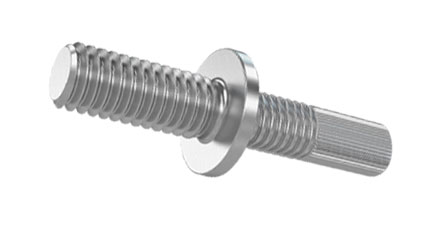

Alufast®

Aluminum screws

Particularly in the automotive industry, the trend is towards lightweight materials. Aluminum and magnesium alloys use are increasing in many fields of technology. So it’s necessary for fastening technology also to adapt too.

Aluminum has very many possibilities because this material is extremely versatile in the cold forming process.

ARNOLD supplies aluminum screws under the Alufast® product name. Our many years of experience working with aluminum ensure that you have the best fastening results. We are continually optimizing our processes to maintain our Alufast® products at the latest state of technology.

Benefits

To gain the maximum benefit from screw strength, we recommend a super-elastic screw assembly, such as using the torque-angle controlled tightening procedure. Due to the material used and depending on the clamping length l K present, sufficient ductility is available. A purely torque controlled screw assembly has a weakness in that the screw-in torque is directly dependent upon the screw’s friction coefficient. That is why we provide various coatings with set friction characteristics.

Characteristics

Aluminum screws from the ARNOLD Alufast® range are primarily used in the automotive industry. We use EN AW 6056 (AlSi1MgCuMn) alloy as our original material, known by its designation class of AL9. Due to the low E-module, the flexibility of an aluminum screw is much greater than that of a steel screw (EAI=70000 MPa, E=210000 MPa).

Advantages

ARNOLD aluminum screws are light, flexible, durable, environmentally sustainable, and corrosion-resistant. Particularly when combined with magnesium, aluminum, or synthetic components, aluminum delivers many positives. Due to the high elasticity of the connection made between the lightweight metal component and the aluminum screw, additional thermally induced stresses on the screw are lower than in comparable applications using steel screws. This minimizes setting, creeping, and pre-clamping force loss. The result is a high degree of assembly reliability. Depending on your requirements, many characteristics can be precisely adjusted through finely-tuned processes.

Particularly in the automotive industry, the trend is towards lightweight materials. Aluminum and magnesium alloys use are increasing in many fields of technology. So it’s necessary for fastening technology also to adapt too.

Aluminum has very many possibilities because this material is extremely versatile in the cold forming process.

ARNOLD supplies aluminum screws under the Alufast® product name. Our many years of experience working with aluminum ensure that you have the best fastening results. We are continually optimizing our processes to maintain our Alufast® products at the latest state of technology.

Characteristics

Aluminum screws from the ARNOLD Alufast® range are primarily used in the automotive industry. We use EN AW 6056 (AlSi1MgCuMn) alloy as our original material, known by its designation class of AL9. Due to the low E-module, the flexibility of an aluminum screw is much greater than that of a steel screw (EAI=70000 MPa, E=210000 MPa).

Benefits

To gain the maximum benefit from screw strength, we recommend a super-elastic screw assembly, such as using the torque-angle controlled tightening procedure. Due to the material used and depending on the clamping length l K present, sufficient ductility is available. A purely torque controlled screw assembly has a weakness in that the screw-in torque is directly dependent upon the screw’s friction coefficient. That is why we provide various coatings with set friction characteristics.

Advantages

ARNOLD aluminum screws are light, flexible, durable, environmentally sustainable, and corrosion-resistant. Particularly when combined with magnesium, aluminum, or synthetic components, aluminum delivers many positives. Due to the high elasticity of the connection made between the lightweight metal component and the aluminum screw, additional thermally induced stresses on the screw are lower than in comparable applications using steel screws. This minimizes setting, creeping, and pre-clamping force loss. The result is a high degree of assembly reliability. Depending on your requirements, many characteristics can be precisely adjusted through finely-tuned processes.