Flowform®

Innovative sheet metal fastening

In sheet-metal joining, the market trend is ever thinner sheet metals, and the fasteners used need to be predominantly high strength. Materials combinations are becoming ever more challenging. This is where conventional joining processes often reach their limits. ARNOLD’s answer to these challenges is called Flowform®. This flow-hole and thread-forming screw from ARNOLD provides a fully automated join, with no pre-drilling required, and single-sided access. Flowform® fastenings is a very economical and reliable joining method.

Benefits

The Flowform® screw comes with two different head variants. They differ principally in the underhead recess and the drive application. The head geometry you choose depends on the application requirements.

Flathead with external driving

- Allows high recess level underhead

- Can accept rising material

- Can join several sheet combinations without a pre-drilled hole

- Distinctive for its low head height

Flathead with internal driving

- Makes it easy to find the force application

- Allows lower underhead recess

- Is very economical

Do you need a special design? Let's talk about other options for your particular application!

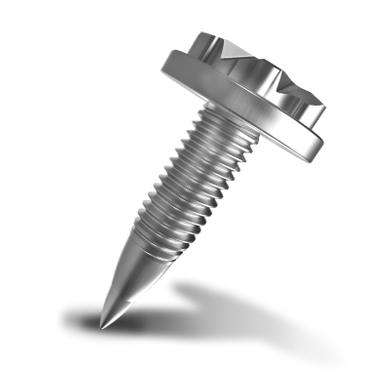

Characteristics

The Flowform® screw heats up and penetrates the sheet metal. With its polygonal tip geometry, it forms a flow-hole then taps a thread. This thread is designed to accept a metric screw if repairs are ever needed. After it has been screwed in, the formed through-hole adjusts optimally to the contours of the screw.

Advantages

- The disproportionately dimensioned thread provides 100% thread cover and high pull-out forces; the formed thread can also accept a metric screw

- Thread-forming area with low thread-forming torques and no chips during the forming

- Slim tip shape – for low joining force, rapid cycle times, short penetration times, low component deformation, and preventing chip formation

- Time and cost-saving – no pre-drilling, no thread-cutting, no chips formed during screw-in, significantly reduced cycle times

In sheet-metal joining, the market trend is ever thinner sheet metals, and the fasteners used need to be predominantly high strength. Materials combinations are becoming ever more challenging. This is where conventional joining processes often reach their limits. ARNOLD’s answer to these challenges is called Flowform®. This flow-hole and thread-forming screw from ARNOLD provides a fully automated join, with no pre-drilling required, and single-sided access. Flowform® fastenings is a very economical and reliable joining method.

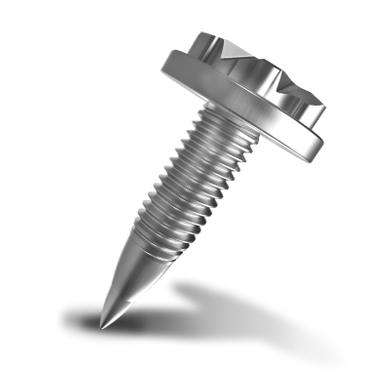

Characteristics

The Flowform® screw heats up and penetrates the sheet metal. With its polygonal tip geometry, it forms a flow-hole then taps a thread. This thread is designed to accept a metric screw if repairs are ever needed. After it has been screwed in, the formed through-hole adjusts optimally to the contours of the screw.

Benefits

The Flowform® screw comes with two different head variants. They differ principally in the underhead recess and the drive application. The head geometry you choose depends on the application requirements.

Flathead with external driving

- Allows high recess level underhead

- Can accept rising material

- Can join several sheet combinations without a pre-drilled hole

- Distinctive for its low head height

Flathead with internal driving

- Makes it easy to find the force application

- Allows lower underhead recess

- Is very economical

Do you need a special design? Let's talk about other options for your particular application!

Advantages

- The disproportionately dimensioned thread provides 100% thread cover and high pull-out forces; the formed thread can also accept a metric screw

- Thread-forming area with low thread-forming torques and no chips during the forming

- Slim tip shape – for low joining force, rapid cycle times, short penetration times, low component deformation, and preventing chip formation

- Time and cost-saving – no pre-drilling, no thread-cutting, no chips formed during screw-in, significantly reduced cycle times