Flexweld®

Resistance element welding

Until recently it was always impossible to join aluminium to hot-formed steel. Flexweld® – ARNOLD's unique resistance element welding technology comes to the rescue. In high-volume production, the new procedure was first used in manufacturing the parcel shelf for the VW’s Passat B8 limousine. The result is that More than 1 kg weight was saved on that component alone.

Benefits

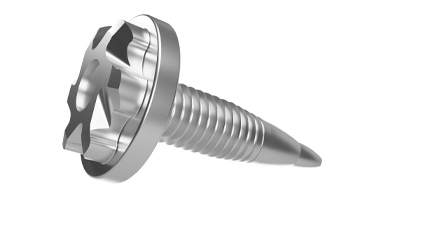

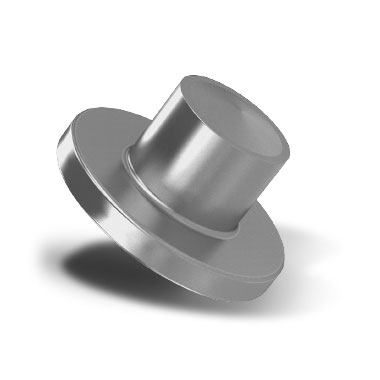

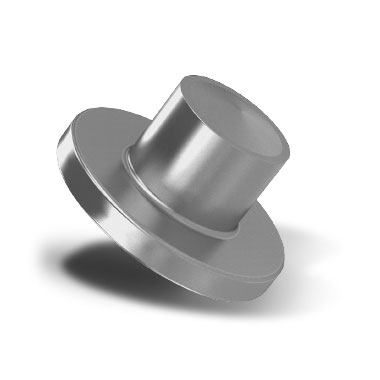

Flexweld® is the only joining procedure that makes it possible to join aluminium to deep-drawn steels and heat-hardened martenistic steel. Once the Flexweld® elements have been inserted into the aluminium sheet, the sheet metal is then fastened to steel sheets using traditional spot welding process in existing production systems.

Characteristics

Flexweld® elements are self-punched into the aluminium sheet where they are permanently fixed. The metal sheet is then welded to the steel components using conventional resistance spot welding tongs, and is also bonded with adhesive.

Advantages

The substantial weight reduction created by Flexweld® is, in these times of lightweight construction, one of the greatest strengths of this ground-breaking system from ARNOLD. There are even more positive points to the system:

- Lightweight materials are joined to maximum high-strength metals

- They can be incorporated into existing assembly lines since it is possible to use the same production and welding equipment

- No need for staff to obtain additional qualifications

- Complete system including full feeder and processing technology

- Mixed production is a possibility if the spot welding tongs software is adapted

Until recently it was always impossible to join aluminium to hot-formed steel. Flexweld® – ARNOLD's unique resistance element welding technology comes to the rescue. In high-volume production, the new procedure was first used in manufacturing the parcel shelf for the VW’s Passat B8 limousine. The result is that More than 1 kg weight was saved on that component alone.

Characteristics

Flexweld® elements are self-punched into the aluminium sheet where they are permanently fixed. The metal sheet is then welded to the steel components using conventional resistance spot welding tongs, and is also bonded with adhesive.

Benefits

Flexweld® is the only joining procedure that makes it possible to join aluminium to deep-drawn steels and heat-hardened martenistic steel. Once the Flexweld® elements have been inserted into the aluminium sheet, the sheet metal is then fastened to steel sheets using traditional spot welding process in existing production systems.

Advantages

The substantial weight reduction created by Flexweld® is, in these times of lightweight construction, one of the greatest strengths of this ground-breaking system from ARNOLD. There are even more positive points to the system:

- Lightweight materials are joined to maximum high-strength metals

- They can be incorporated into existing assembly lines since it is possible to use the same production and welding equipment

- No need for staff to obtain additional qualifications

- Complete system including full feeder and processing technology

- Mixed production is a possibility if the spot welding tongs software is adapted

Your benefits with ARNOLD: a comprehensive complete solution from a single supplier

The appropriate system technology is the best way to complement the fasteners supplied by ARNOLD and achieve perfect implementation of your project. So you have a single point of contact for all the components of the production process.

We provide you with all the joining parameters you need to ensure the best possible preparation for production. You can start pre-series production quickly, making modifications if necessary, and then you can start series production on a strong footing. The result is that you save a great deal of time and money at the critical start-up and ramp-up stages.