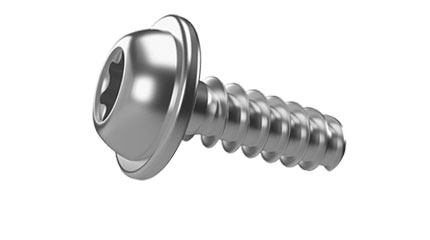

TAPTITE 2000®

Thread-tapping in metal

TAPTITE 2000® is a thread-tapping screw with outstanding mechanical, fastening and ergonomic characteristics.

Compared with conventional screws, with TAPTITE 2000® you can reduce your overall fastening costs by up to 85%, partly because the cost of manufacture is drastically reduced: Many steps of the process can simply be omitted. The fastener is screwed straight into a cast or drilled core hole.

Benefits

When you use TAPTITE 2000®, you reduce processing time as well as tool and machine usage.

Example: the machining centre and the washing unit can be omitted for the screw locations, as would be necessary for threaded screws, and there's no need to purchase measuring instruments to check gauge sizes, and no additional locking elements are needed.

Characteristics

Using TAPTITE 2000® ensures that in metal-joining applications, you can eliminate work processes such as thread cutting. And there is no need for additional fastening elements.

Advantages

The TAPTITE 2000® thread profile is similar to the involute shape of a gearwheel. Together with the triangular (trilobular™) cross-section geometry of the screw's shaft, it greatly improves the mechanical properties of the screw fastening. This means

- Less forming effort and material displacement during the thread-tapping process – the material can flow more easily in the direction of the thread core

- The material's grain direction is preserved

- The mechanical values of the material can be increased during strain hardening by around 30%.

- Chip-less thread-forming (no chips are formed as is the case with cutting screws)

- Lower screw-in torque and lower clamping force scatter

- Higher pre-load forces and greater vibration resistance

TAPTITE 2000® is a thread-tapping screw with outstanding mechanical, fastening and ergonomic characteristics.

Compared with conventional screws, with TAPTITE 2000® you can reduce your overall fastening costs by up to 85%, partly because the cost of manufacture is drastically reduced: Many steps of the process can simply be omitted. The fastener is screwed straight into a cast or drilled core hole.

Characteristics

Using TAPTITE 2000® ensures that in metal-joining applications, you can eliminate work processes such as thread cutting. And there is no need for additional fastening elements.

Benefits

When you use TAPTITE 2000®, you reduce processing time as well as tool and machine usage.

Example: the machining centre and the washing unit can be omitted for the screw locations, as would be necessary for threaded screws, and there's no need to purchase measuring instruments to check gauge sizes, and no additional locking elements are needed.

Advantages

The TAPTITE 2000® thread profile is similar to the involute shape of a gearwheel. Together with the triangular (trilobular™) cross-section geometry of the screw's shaft, it greatly improves the mechanical properties of the screw fastening. This means

- Less forming effort and material displacement during the thread-tapping process – the material can flow more easily in the direction of the thread core

- The material's grain direction is preserved

- The mechanical values of the material can be increased during strain hardening by around 30%.

- Chip-less thread-forming (no chips are formed as is the case with cutting screws)

- Lower screw-in torque and lower clamping force scatter

- Higher pre-load forces and greater vibration resistance

TAPTITE 2000® is a trademark licensed by CONTI Fasteners AG